About Us

Transforming Industries with Cutting-Edge Vacuum Coating Innovations

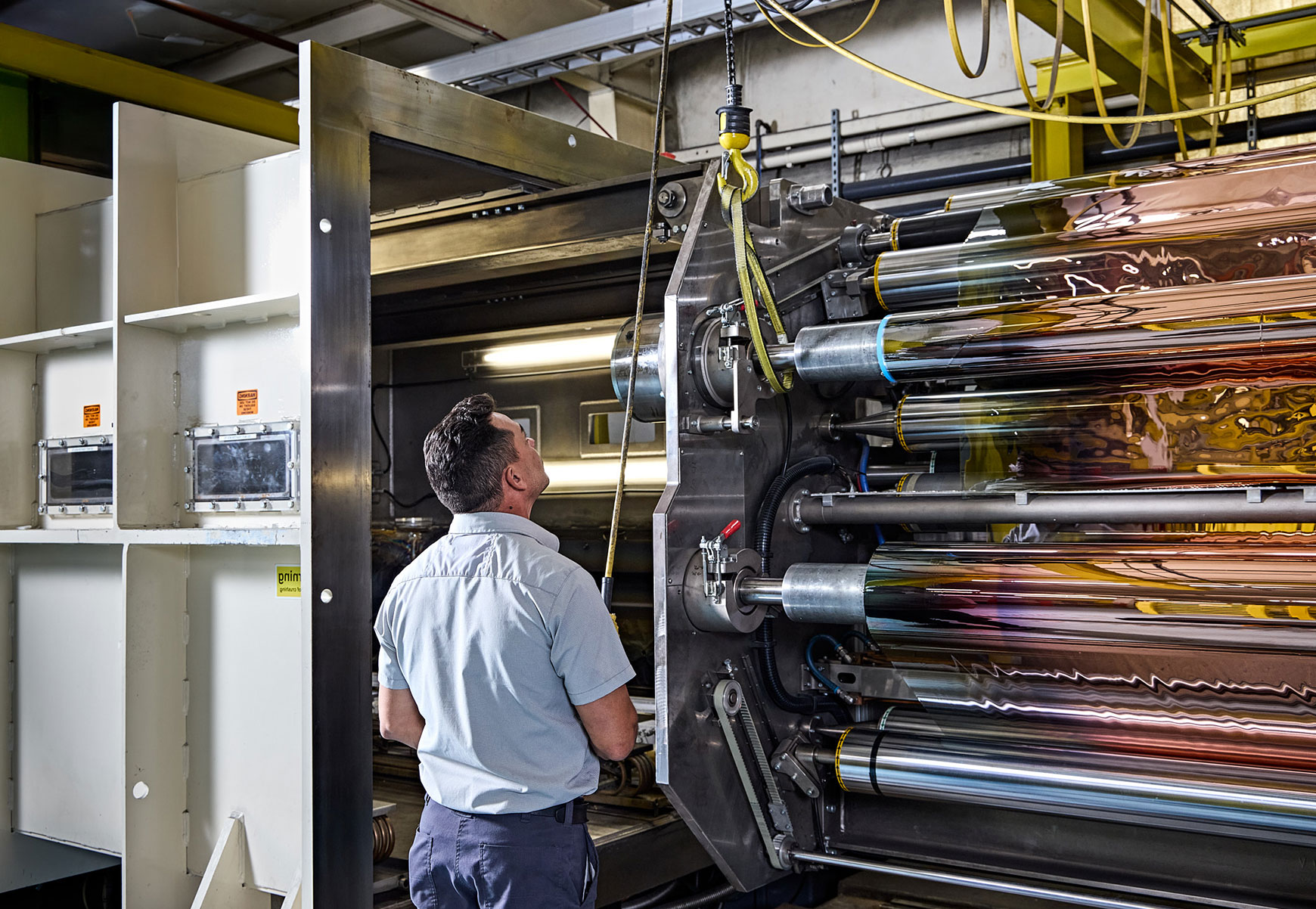

With decades of experience, Vacuum Depositing Inc (VDI) is a trusted leader in providing specialized roll-to-roll vacuum coating solutions. Our state-of-the-art facility, coupled with a team of skilled professionals, enables us to deliver advanced thin film products for diverse industries. From healthcare to electronics, textiles to automotive components, our focus is on delivering exceptional quality and innovative solutions that meet our clients' exact requirements.

Our Services

Your One-Stop Shop

VDI uniquely offers state-of-the-art evaporative, sputtering, and e-beam capabilities all under one roof located in the heart of America. Combined with the solution coating and laminating capabilities of Madico®, our technical abilities are surpassed only by our attention to quality and service.

- Metallizing

- Slitting

- Coating & Laminating

Metallizing

VDI offers three state-of-the-art metallization processes at its Louisville location.

Slitting

VDI offers customized

slitting and rewinding both

pre- and post-metallization. Key capabilities include:

- Handling of up to 80-inch-wide master rolls with our slitting machines.

- Ability to cut to a minimum width of 4 inches.

Coating & Laminating

Madico®, a subsidiary of VDI’s parent company, Lintec Corp.,

is a world leader in

coating, laminating, and converting of films

in wide width, roll-to-roll format.

Applications

Transforming Industries with Tailored Applications

- Sputtered Coatings Applications

- Thermal Evaporative Applications

- Electron-Beam Applications

Sputtered Coatings Applications

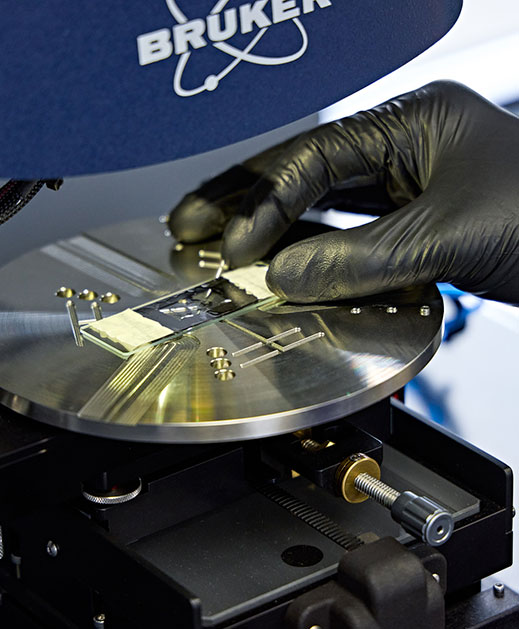

VDI's evaporative deposition services offer a versatile solution for applying film coatings on various substrates such as PET, Nylon, fabrics, foils, and other web polymers. This capability allows for precise control of film thickness and uniformity, enabling applications in industries such as electronics, optics, and packaging.

Key Applications

- Data Storage: Thin magnetic layers in hard drives.

- Transparent Conductive Oxides: Coatings on displays and touch screens.

- Barrier Films: Packaging layers for gas/moisture prevention.

- Microelectronics: Thin film resistors and capacitors.

- Optical Coatings: Anti-reflective coatings, mirrors, filters.

- Thermal Control: Reflective coatings on spacecraft/satellites.

- Solar Cells: Absorbing layers and back contacts in PV cells.

- Biomedical

- Decorative

Thermal Evaporative Applications

VDI's roll-to-roll thermal evaporation technique is designed to handle web widths up to 80 inches and film thicknesses ranging between 36GA and 1000GA (9µm to 250µm).. This evaporation process is well-suited for flexible substrates like PET, Nylon, various web polymers, fabrics, and foils, ensuring consistent film thickness and uniformity across diverse applications.

Key Applications

- Optical Coatings: Anti-reflective lenses, mirrors.

- Solar Cells: Layers in thin-film photovoltaic cells.

- Protective Coatings: Corrosion-resistant layers, environmental barriers.

- Decorative Coatings: Metallic finishes on products.

- Magnetic Storage: Thin magnetic layers in storage devices.

- Wear Resistant Coatings: Hard coatings on tools/parts.

- Research & Development: Prototype development, thin film samples.

- OLEDs: Organic layers deposition.

- Sensors: Thin film sensor layers.

- Barrier Films: Barrier layers in packaging.

Electron-Beam Applications

VDI's electron-beam deposition process accommodates web widths up to 80 inches and film thicknesses ranging from 36GA and 1000GA (9µm to 250µm). This technique is typically applied to substrates such as PET, Nylon, various web polymers, fabrics, and foils, ensuring precision and adaptability for diverse applications.

Key Applications

- Microelectronics: High-purity metal films for circuits.

- Optical Coatings: Precision anti-reflective, high-reflective, filter coatings.

- Research & Development: Thin film materials studies.

- Metallic Contacts: Thin metal contacts on electronic components.

- Barrier Films: Ultra-thin protective coatings.

- Magnetic Films: Layers for magnetic data storage.

- Decorative Coatings: High-quality finishes on goods.

- Surface Passivation: Protecting substrates from environmental effects.

- Solar Cells: Layers in advanced PV cells.

News & Articles

Latest Blog Posts

What is ITO Sputter Deposition

Indium Oxide/Tin Oxide is among one of the most heavily utilized compounds in the thin film industry due to its electrical conductivity and optical transparency.

Learn more

Vacuum Deposition: A Guide to Thin Film Coating Techniques

One common method for producing thin films is evaporative deposition, which involves the vaporization and subsequent

Learn more

VDI’s Product Development Engineer Receives Technical Award at AIMCAL R2R Conference 2019

Rob Malay, Ph.D., Product Development Engineer at VDI, was the recipient of the John Matteucci Technical Excellence Award at this year’s AIMCAL R2R Conference 2019.

Learn more

VDI Product Development Manager highlights manufacturing advances

Robert Malay, Ph.D., Product Development Manager at VDI, recently co-authored an article for Converting Quarterly entitled “Establishing the flexible-glass R2R coating ecosystem.”

Learn more

VDI Invests in New Equipment, Increases Capacity

VDI today announces a significant investment in new equipment for improved manufacturing with the purchase of a new, world-class vacuum metallizer.

Learn more

Lintec (LUSA) acquires Vacuum Depositing, Inc.

Lintec USA Holding, Inc., a subsidiary of Lintec Corporation, announced today that it has entered into a definitive agreement to acquire Vacuum Depositing, Inc...

Learn more

Ready to Take the Next Step

Ready to explore how VDI's advanced vacuum coating solutions can elevate your products and applications? Contact us today for a free consultation with our experts.

Get a Free Consultation