What is Electron-Beam Deposition?

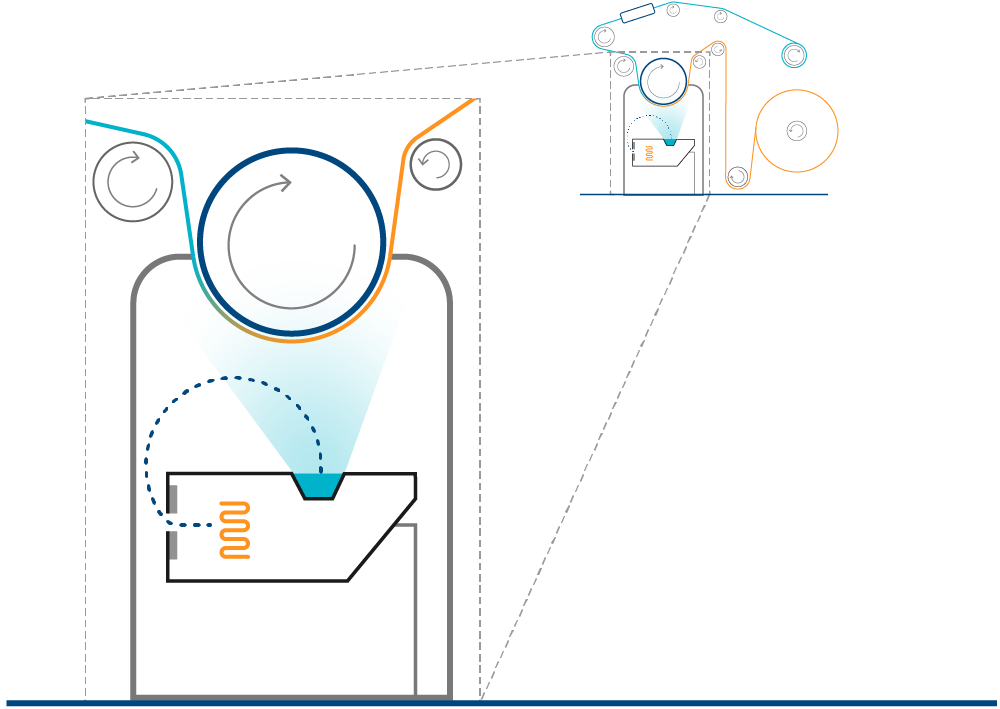

Electron-beam deposition is a state-of-the-art thin film deposition process where an electron gun is used to vaporize target materials in a high vacuum environment, facilitating the subsequent condensation of these materials as a film on the desired substrate.

Electron-beam deposition is a cutting-edge technique in the realm of thin film deposition. At its core, this method revolves around the use of an electron gun—a sophisticated device that emits a focused stream of high-energy electrons. This stream is directed towards specific target materials, typically metals, alloys, or dielectrics, housed within the deposition chamber.

When these high-energy electrons collide with the target material, they impart their energy, causing the material to heat up rapidly. This intense localized heating leads to the vaporization of the target material. As this process is carried out in a high vacuum environment, the vaporized atoms or molecules of the target material become highly mobile, traveling freely within the chamber.

The substrate, which is the material onto which the film is to be deposited, is strategically positioned within the chamber. As the vaporized target material atoms or molecules encounter the cooler substrate, they condense onto its surface, forming a thin, uniform film.

It's the precision of the electron gun, combined with the controlled vacuum conditions, that allows for the deposition of extremely thin, yet uniform and high-quality films. This ensures that the resulting films have consistent properties, making electron-beam deposition an ideal choice for applications that demand exacting standards.

VDI's Electron-Beam (e-beam) Deposition Capabilities

Outlined below are some of the general capabilities of VDI’s evaporation (vapor) services. For a full list of metals and applications supported please contact us.

E-Beam Deposition

Electron-beam deposition is a thin film deposition technique that uses an electron gun to vaporize target materials in a vacuum, allowing them to condense and form a uniform film on a substrate.

Deposition Method

Electron Beam, 8 electron guns / closed loop system, VLT monitoring

Substrate Widths

Web widths up to 74 inches

* - Various alloys supported including inconnel and stainless steel. Dielectric materials include silicon dioxide (SiO2) and titanium dioxide (TiO2).

Substrates Supported (Partial)

- PET

- Nylon

- Fabrics

- Foils

- Synthetic Paper

Metals Supported*:

Applications

Electron-beam deposition finds applications in diverse fields such as electronics, optics, and aerospace engineering. This technique is prized for its ability to produce extremely pure and defect-free thin films with remarkable precision in thickness and composition. With our advanced technology, we offer unparalleled uniformity and tight tolerances in metal deposition across roll-to-roll processes. Our specialized pre-treatment procedures further enhance the adhesion qualities of the deposited metals, ensuring superior performance and durability in the end products.

Additional applications:

- aerospace

- Window Film Components

- Thin-Film Transistors

- Solar Panels

- Flexible and Foldable Displays

- Barrier Films

- Anti-reflective Coatings

- Mirror Coatings

- Microelectromechanical Systems (MEMS)

- RFID Tags

- Sensors

- Enhanced Metal Adhesion Applications

- Thermal and Protectinve Fabrics

Industries

In the electronics industry, roll-to-roll electron-beam deposition is employed for the fabrication of thin-film components in flexible displays and solar panels. The technology offers high material purity and precise control over film thickness, which is essential for ensuring the high performance and long-term durability of these products.

In aerospace, automotive, and medical applications, electron-beam deposition serves specialized needs. For aerospace and automotive components, the technique is used to apply highly durable, wear-resistant coatings that can withstand extreme environmental conditions. In the medical sector, electron-beam deposition provides the means to apply biocompatible coatings on implants and surgical instruments, enhancing both their safety and functionality. The roll-to-roll approach facilitates the high-volume, cost-effective manufacturing of these essential coatings and films, making electron-beam deposition a valuable tool across multiple industries.

Additional Industries:

- Electronics and Semiconductors

- Solar Energy

- Flexible Display Manufacturing

- Aerospace

- Automotive

- Packaging

- Medical Devices

News & Articles

Latest Blog Posts

What is ITO Sputter Deposition

Indium Oxide/Tin Oxide is among one of the most heavily utilized compounds in the thin film industry due to its electrical conductivity and optical transparency.

Learn more

Vacuum Deposition: A Guide to Thin Film Coating Techniques

One common method for producing thin films is evaporative deposition, which involves the vaporization and subsequent

Learn more

VDI’s Product Development Engineer Receives Technical Award at AIMCAL R2R Conference 2019

Rob Malay, Ph.D., Product Development Engineer at VDI, was the recipient of the John Matteucci Technical Excellence Award at this year’s AIMCAL R2R Conference 2019.

Learn more

VDI Product Development Manager highlights manufacturing advances

Robert Malay, Ph.D., Product Development Manager at VDI, recently co-authored an article for Converting Quarterly entitled “Establishing the flexible-glass R2R coating ecosystem.”

Learn more

VDI Invests in New Equipment, Increases Capacity

VDI today announces a significant investment in new equipment for improved manufacturing with the purchase of a new, world-class vacuum metallizer.

Learn more

Lintec (LUSA) acquires Vacuum Depositing, Inc.

Lintec USA Holding, Inc., a subsidiary of Lintec Corporation, announced today that it has entered into a definitive agreement to acquire Vacuum Depositing, Inc...

Learn more

Ready to Take the Next Step

Ready to explore how VDI's cutting-edge vacuum coating solutions can elevate your products and applications? Contact us today for a free consultation with our experts.

Get a Free Consultation